You need an account to access this content

Create a free account and get access to all downloads and more!

ComAp’s CHP smart control solutions enable fast and easy control of your gen-sets and CHPs. With tens of thousands of projects implemented worldwide, we offer proven expertise and solutions for any type of project, regardless of complexity — from small to large sites, island to network-parallel operations, and pure power production to complex CHPs.

Reduce time to market

Our pre-programed solution allows you to control the gas gen-set very quickly, saving you time to focus on developing your expertise and business.

Realise any project, regardless of size or complexity

Not all projects are the same and customers can come to you with demanding requirements. ComAp’s solution enables you to adapt to such requirements in a very short time. The configurable internal PLC interpreter offers easy customisation, allowing you to implement almost any change and function on your own, keeping your valuable know-how in your company.

Maximise the solution uptime

Power generation or CHPs are making money when they are running or are available to run. When issues and interruptions occur, it is essential to immediately find and resolve them. ComAp offers detailed diagnostics of the whole control process for early problem detection, as well as a notifying system with alarms and messages to keep your system up and your operations efficient.

ComAp’s solution for gas gen-sets and CHP are being used by various customer groups. The solution meets the variety of requirements typical for CHP packagers, the demanding legislation requirments typical for OEMs, and it also meets the flexibility requirements set by system integrators and retrofitters.

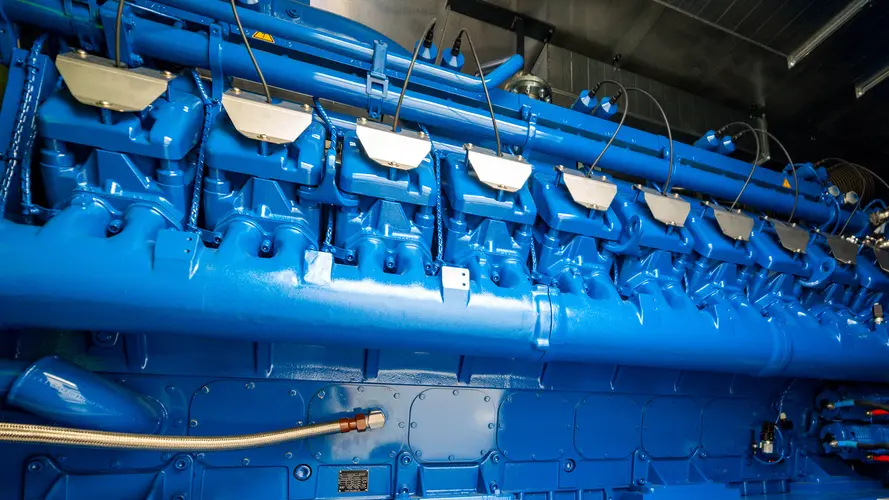

MAN® gas engines are very popular in the power generation industry, especially with packagers. Our ComAp control system is compatible with these gas engines and has been implemented on thousands of different types of MAN® engines.

Our system controls the whole engine, alternator and the final application, e.g., CHP, providing customers with numerous benefits including fast time to market, the possibility to design simple and very complex projects and helping them to maximise the solution uptime.

ComAp's control system is the No.1 option for major packagers of MWM® gas engines and gen-sets. With our solution these customers benefit from an easy interface with the MWM® engine control system, they get a simple solution for alternator control and easy implementation of the CHP part, which is available for them without any additional costs.

ComAp's control system can be used on top of Jenbacher®'s gen-sets in cases where these machines are added to an existing fleet of gen-sets from different brands and there is a need for unified power management and load sharing.

ComAp takes care of running of the entire site optimisation to reduce fuel consumption, emissions and operational costs.

ComAp is one of the factory default systems used on Cummins® HSK78G gas gen-sets. End customers using this Cummins® gas gen-set can benefit from ComAp's intuitive and simple system, providing smart control operations both locally on site and remotely around the globe.

ComAp offers a large number of compatible ECUs and control systems which we can interface to easily. Apart from engine control unit interface, ComAp's system typically controls the alternator and the final application, helping our customers meet various requirements - from customer-specific ones, such as running schemes, to legislative requirements, such as Grid connections.

These solutions can be implemented for CAT, Siemens (Guascor), Cummins, and other types of engines.

If your gas engine does not have any control system or unit installed, ComAp can help you handle it. Our solution controls the entire engine, processing all engine and application sensors such as the ones for pressure, temperature, levels etc. This helps secure safe and optimal running of the engine.

In addition, we take care of the alternator and the final application where the gen-set is used - e.g. a CHP. Typical examples of these solutions in practice are for MAN gas engines, Perkins and others.

Didn't find what you were looking for? Contact us, we’ll be happy to answer any questions you may have and help you with your business needs.

Interested in another country? Find your local representative.